Feeding & Dosing Machines

Volumetric Feeder

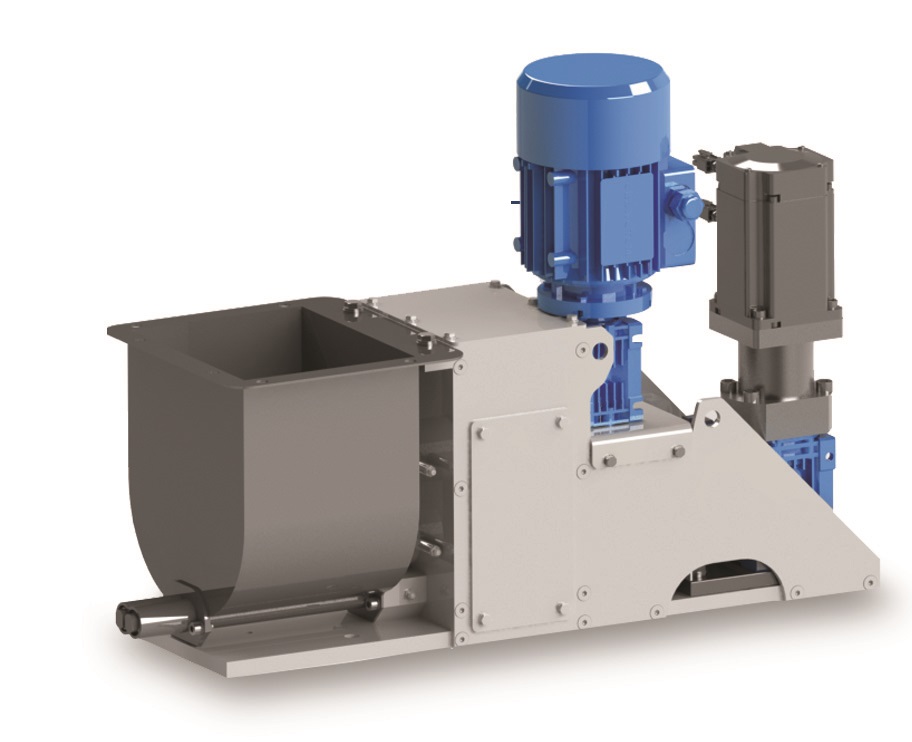

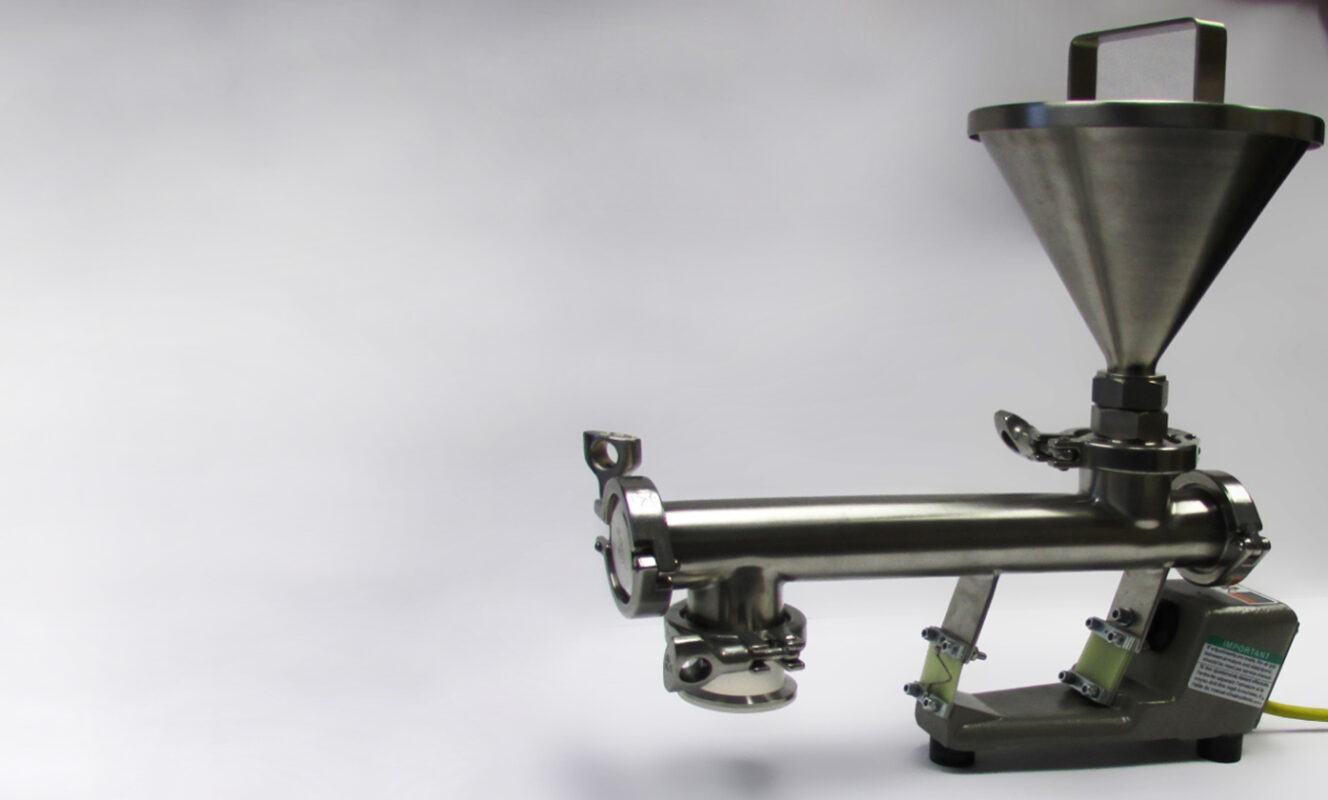

Behpoo Volumetric Feeders

Behpoo volumetric feeders are produced in various configurations and sizes, including vibratory and screw types. These systems are designed with open-loop control to deliver appropriate accuracy and reliability for their intended applications.

Description

Various forms of bulk dry materials (batch, powder, granular, etc.) can be fed or transferred using feeders.

As the name implies, a volumetric feeder operates according to the volume that a substance takes up. A specific volume of material is gathered in the feed trough as the screw rotates and they are usually mechanically fed by one or two screws. Subsequently, the screw or screws drive this forward, and it escapes through the output tube to the process equipment downstream.

Depending on the capacity and requirements of the client, Behpoo volumetric feeders are designed and manufactured in single screw, twin screw, and vibrating types.

One issue with this approach is that when the feeder is empty, the machine is not aware of it. The controls are designed based on the motor driving the screws, causing them to rotate at a consistent rate regardless of the amount of material on the feeder.

When the material undergoes a change in density, forms bridges above the feed trough, or alters its flow behavior, the control system will not respond. It will continue operating at a consistent speed, maintaining the same output until an external action changes its speed.

Benefits & Features

- High Accuracy (1.5-2.5 %)

- Reliable

- Available in Various Configurations and Sizes

- Modular Design

- Available In Suspension and Platform Types

Areas & Application

Plastics Processing: Compounding, extrusion, and injection molding operations in the plastics sector rely heavily on volumetric feeders. They ensure consistent product composition and quality by metering virgin resins, colorants, and additives. They can be utilized as refill devices, bin dischargers, and material transfer into conveying lines.

Food Processing: These feeders are widely used in the food industry for a variety of purposes, including dosing materials for baking and confectionery applications and transporting spices and flavorings. Their ability to precisely measure and maintain sanitary design makes them an invaluable tool for guaranteeing product integrity and adherence to food safety regulations.

Pharmaceutical Manufacturing: To precisely dispense , various powdered or granular materials, and active pharmaceutical ingredients (APIs), volumetric feeders are used in pharmaceutical manufacture. Their precise dosing capabilities and hygienic design are essential for guaranteeing both product performance and regulatory compliance.

Chemical and Petrochemical Processing: These feeders make it easier to measure catalysts, additives, and raw materials for a variety of chemical and petrochemical processes, including mixing, reaction, and formulation. They are appropriate for handling caustic materials because of their sturdy build and chemical resistance.

Construction Materials: To ensure accurate and constant dosing of additives, fillers, and aggregates in the manufacturing of concrete, mortar, and composites, industries producing construction materials rely on volumetric feeders.

Available Models

| Specification | FDR-DS18 | FDR-DS37 | FDR-DS70 | Customized model |

| Discharge Rate (Lit/h) | 3-30 | 20-600 | 500-3000 | Customized |

| Feeding Accuracy | 1.5 – 2.5% | 1.5 – 2.5% | 1.5 – 2.5% | 1.5 – 2.5% |

| Chassis Material | Stainless steel/ painted plate carbon | Stainless steel/ painted plate carbon | Stainless steel/ painted plate carbon | Stainless steel/ painted plate carbon |

| Size of the Inlet Funnel (Lit) | 10 | 40 | 80 | customized |

| Screw Diameter | 20 | 40 | 80 | customized |

Product contact parts are manufactured of stainless steel.

Hazardous location options (ATEX, NEC) available.

Download the Product Specification Sheets

| Specification | FDR-DS18 | FDR-DS37 | FDR-DS70 | Customized model |

| Discharge Rate (Lit/h) | 1-20 | 10-500 | 200-5000 | Customized |

| Feeding Accuracy | 1.5 – 2.5% | 1.5 – 2.5% | 1.5 – 2.5% | 1.5 – 2.5% |

| Chassis Material | Stainless steel/ painted plate carbon | Stainless steel/ painted plate carbon | Stainless steel/ painted plate carbon | Stainless steel/ painted plate carbon |

| Size of the Inlet Funnel (Lit) | 10 | 40 | 80 | customized |

| Screw Diameter | 18 | 37 | 70 | customized |

Product contact parts are manufactured of stainless steel.

Hazardous location options (ATEX, NEC) available.

Download the Product Specification Sheets

| Specification | |

| Discharge Rate (Lit/h) | 0.1-10000 |

| Feeding Accuracy | 1-2 % (Depending on the Product) |

| Chassis Material | Stainless steel / painted plate carbon |

| Size of the Inlet Funnel (Lit) | 5-100 |

Product contact parts are manufactured of stainless steel.

Hazardous location options (ATEX, NEC) available.