Feeding & Dosing Machines

Gravimetric Feeder

Behpoo LIW & GIW Feeders

Behpoo gravimetric feeders are designed with high measurement accuracy and exceptional reliability in various configurations and sizes for dosing powders and granules with different physical conditions.

Description

Gravimetric feeders integrate a volumetric feeding device within an advanced system that measures the mass of the material being fed. A weighing system, such as a weigh scale or load cells, monitors the weight of the hopper, feeder, and material. This data is transmitted to a controller, which accurately determines and regulates the material feed rate.

They are designed to precisely measure and control the material's injection rate into the process. Their closed- loop control system allows for precise adjustments to the feeder's speed to maintain the required material flow rate, achieving accuracy levels that can be better than 1%, depending on the material and installation environment.

These feeders classified into two main categories: Loss-inWeight (LIW) and Gain-in-Weight (GIW), based on how the weight is measured and the placement of the load cells.

Behpoo designs and manufactures both GIW and LIW systems with high accuracy and native design, tailored to meet the specific needs of each client.

Benefits & Features

- High Accuracy (0.5-1 %)

- Reliable

- Available in Various Configurations and Sizes

- Modular Design

- Available In Suspension and Platform Types

Areas & Application

LIW feeders are widely used across diverse industries thanks to their precision, reliability, and efficiency in material handling. Key application areas include:

- Petrochemical Industry: LIW feeders are essential for precise feeding of components in petrochemical plants, supporting smooth and safe operation of automated systems.

- Mining and Mineral Processing: They handle abrasive and heavy materials efficiently, ensuring consistent feeding and reducing downtime in mining operations.

- Pharmaceutical Industry: Handle delicate items like pills and capsules gently, preserving product quality.

- Food Processing: Used for hygienic and efficient feeding of small food items.

- Packaging Lines: Facilitate quick and orderly feeding of parts into packaging machines, boosting productivity.

- With their durability, flexibility, and accuracy, LIW feeders are vital in optimizing automated processes, especially in challenging sectors such as petrochemicals and mining.

Available Models

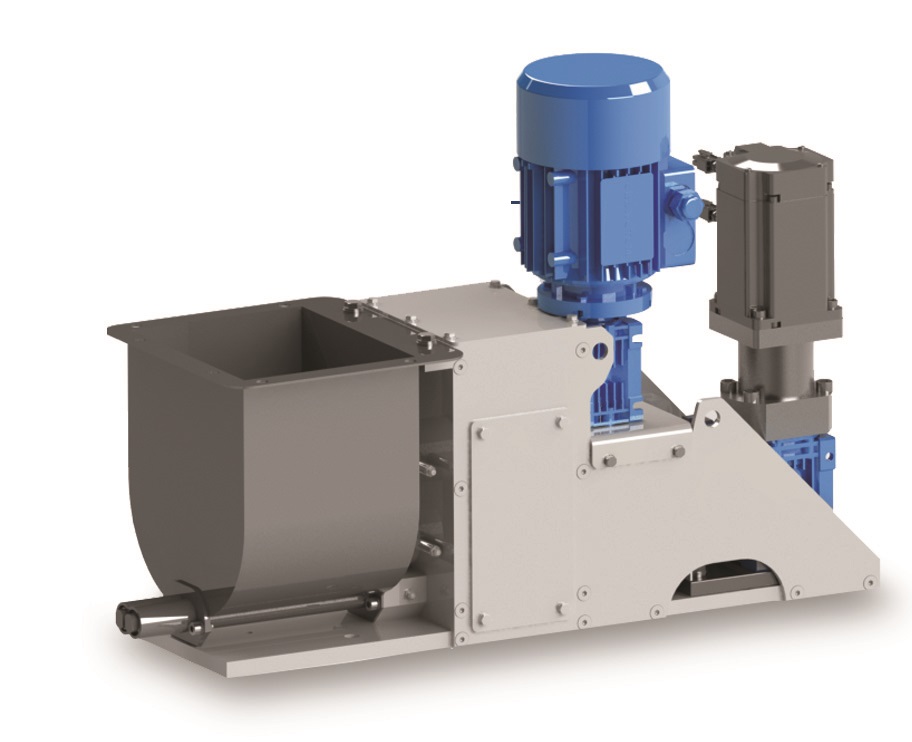

Feed Rates

| Specification | |

| Discharge Rate (Lit/h) | 1-20 |

| Feeding Accuracy | 0.5 – 1 % (Depending on the Product) |

| Chassis Material | Stainless steel / painted plate carbon |

| Size of the Inlet Funnel (Lit) | 10 |

| Screw Diamater | 18 |

Product contact parts are manufactured of stainless steel.

Hazardous location options (ATEX, NEC) available.

Download the Product Specification Sheets

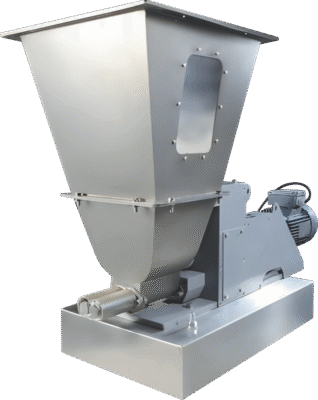

Feed Rates

| Specification | |

| Discharge Rate (Lit/h) | 10-500 |

| Feeding Accuracy | 0.5 – 1 % (Depending on the Product) |

| Chassis Material | Stainless steel / painted plate carbon |

| Size of the Inlet Funnel (Lit) | 40 |

| Screw Diamater | 37 |

Product contact parts are manufactured of stainless steel.

Hazardous location options (ATEX, NEC) available.

Download the Product Specification Sheets

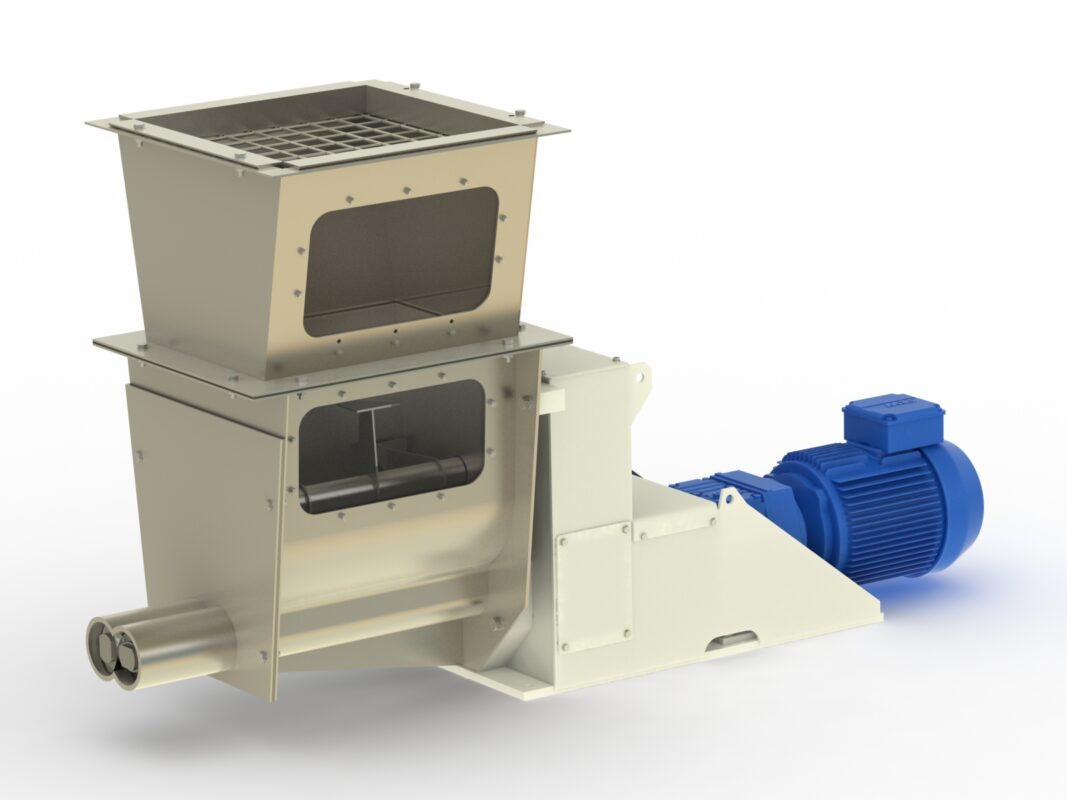

Feed Rates

| Specification | |

| Discharge Rate (Lit/h) | 200-5000 |

| Feeding Accuracy | 0.5 – 1 % (Depending on the Product) |

| Chassis Material | Stainless steel / painted plate carbon |

| Size of the Inlet Funnel (Lit) | 80 |

| Screw Diamater | 70 |

Product contact parts are manufactured of stainless steel.

Hazardous location options (ATEX, NEC) available.